Canting is a tool likes a small cup with two pipe-ends, one of the pipe-ends has an opening, and the other has not and it is the tail (nozzle) of the copper cup.

Kinds of canting used:

- Canting Klowong: This is used in the early phase, that is to apply thin wax-layer on the motif pattern of the batik picture. Its nozzle's opening is of medium size.

- Canting Cecek: This is used to make dots ("cecek") on the motif. Its nozzle's opening is of small size.

- Wall Canting: This is used to give wax layer to a large enough area. Its nozzle's opening is of big size.

The wax used in the process of making batik is the result of composition from paraffin. White paraffin is used in dry season and yellow paraffin is used in rainy season. Its main ingredient is bee wax.

Gondorukem (a chemical compound from plant) functions as a glue between wax and cloth. Gondorukem originates from pine.

Damar ("cat's eye") originates from damar tree, its function is to make the wax harden quickly upon touching the cloth.

Fat is used to speed up the process of melting of the bee wax and to make the wax become easier to get away from the cloth in a process named "nglorod". The fat originates from plant or animal.

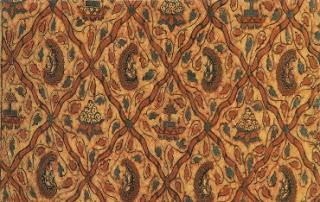

Process of Making Batik

The following are processes of making batik in sequential order from start to finish. The name of method of work may differ between geographic regions that produce batik, but the core of the work itself is the same.

1. Ngemplong

Ngemplong is the earliest stage or preliminary stage, it is started by washing the white cloth. The purpose is to get rid of the "kanji" (porridge of cassava root i.e. the stuff that makes the cloth stiff). This is followed by "pengeloyoran", that is immersion of the white cloth into castor oil or peanut oil that already contained straw ash. The white cloth is immersed into castor oil to get rid of the stiffness, so it will have more capacity to absorb dye (coloring agent).

Ngemplong is the earliest stage or preliminary stage, it is started by washing the white cloth. The purpose is to get rid of the "kanji" (porridge of cassava root i.e. the stuff that makes the cloth stiff). This is followed by "pengeloyoran", that is immersion of the white cloth into castor oil or peanut oil that already contained straw ash. The white cloth is immersed into castor oil to get rid of the stiffness, so it will have more capacity to absorb dye (coloring agent).After undergoing the above-mentioned processes, the cloth is given kanji again and is exposed to the sun light out door. Then, the cloth undergoes "pengemplongan" process, that is the white cloth is hitted repeatedly with a wooden hammer to make it more smooth so it can be painted more easily.

2. Making lines or making pattern on a white cloth (Nyorek)

Making lines or pattern is the process of imitating/copying an existing motif pattern on a white cloth. The pattern is initially made on a paper, and then is copyed on a white cloth.

This stage can be done directly on the cloth or by imitating it (using pencil or canting). But in order to get a good result from coloring process (perfect and not broken), the process of making batik need to be repeated on the opposite side of the cloth. This process is called "ganggang".

3. Making batik painting using canting (Mbathik/ Nyanting/ Klowong)

Making batik painting is the next stage, this is done by applying colored wax on a white cloth, it is started by making lines outside the pattern and filling the pattern with various forms. In the filling process there is a step called "nyecek", that is making "isen-isen" (giving contents by making dots in the already made pattern). There is also an esentially similar step but more detailed, it is called "nruntum".

4. Nembok ("making wall")

"Making wall" is the process of covering parts that may not be colored by the basic color (using wax), in this case is the blue color. The parts are covered by thick layer of wax, as if it is the restraining wall.

5. Medel (dyeing by immersing)

This is the process of dyeing cloth that has been painted by immersing it into coloring fluid repeatedly until the cloth attain the color wanted.

6. Ngerok (scratching) and Mbirah (washing)

In this process, the wax that adhered on the cloth is scratched carefully using a thin piece of metal, then the cloth is washed using clean water and then the cloth is exposed to wind.

7. Mbironi

Mbironi is covering the blue color and covering content of pattern (which are in the form of "cecek" or dots) using wax. There is also another process called "ngrining", this is the process of filling parts (that is still not colored) with certain motif. Usually, ngrining is performed after coloring process.

8. Menyoga

"Menyoga" originates from the word "soga", it is the name of a kind of wood that is used to acquire brown color. This is done by immersing the cloth into a brown liquid.

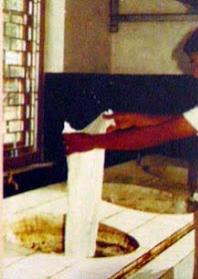

9. Nglorod

"Nglorod" is the finishing step in the process of making batik cloth (written batik or stamped batik), this process uses color restraint (wax). In this stage, the maker gets rid of all wax by immersing a cloth (that has already deep color) in a boiling water. Then the cloth is washed using clean water and then the cloth is exposed to wind until becomes dry. Indeed, the process of makig batik takes long time.

The process, from start to finish, may involves several persons, and every single stage in the process also takes time. That is why, it is very reasonable that the price of a written batik cloth is very expensive.